1960s

It was in the late 1960s and we were working at Fermilab. There were a number of us British expatriates there. It was called the “brain drain” because many large government-funded projects needed help from Europe. The space program, high-energy physics research and various nuclear power undertakings competed with each other for the inadequate number of qualified American technologists needed, and aid from abroad was welcomed.

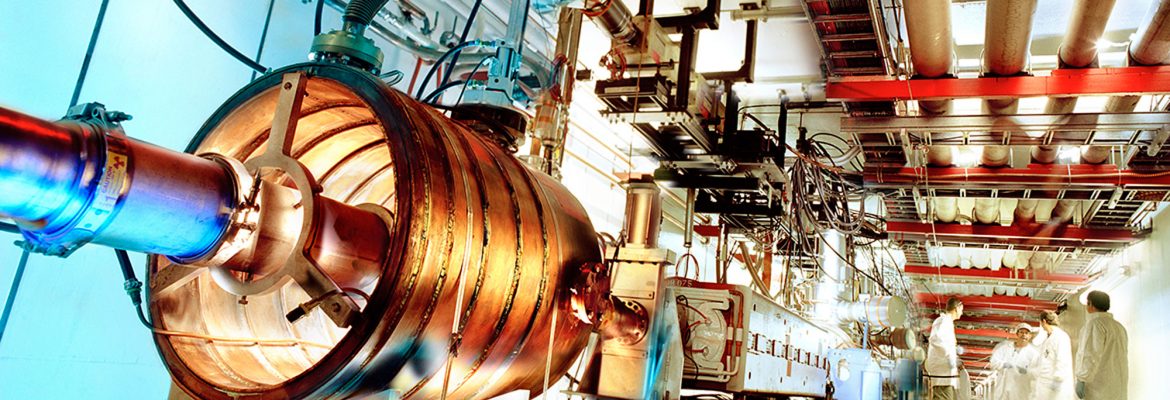

My English friend Roy Billinge had been given a sizeable responsibility involving the construction of the main components of a particle accelerator on a 10-square-mile site on the prairie, 40 miles from Chicago. The budget allotted by Congress was adequate, but the time scale was tight. The success of the project hinged on each needed item being available on time. A delay with a critical component could slow the project down or even cause it to fail.

Roy, a manager who could be relied upon to take ingenious original decisions, decided to import some talent from England. He found a worker at a laboratory near Oxford who was known for his entrepreneurial skills. His name was Bob Sheldon. He would join the project as a fixer, and his specific responsibility was to look out for items with a long delivery delay and try to find alternative sources. At the same time he was to keep an eye open for possible shortcuts and money-saving ideas. A process like that, competently pursued, could easily save enough money and time for his salary to be insignificant.

It worked! Bob brought his wife from England, and the two of them were a wonderful addition to the social life at the lab too. Bob was an affable North-countryman with an expansive personality and got on well with people. Any engineer or physicist in the team who was placing an order for raw materials, machines or high-tech instrumentation would first consult Bob, who made some inquiries and often found a solution that saved time or cost less.

The accelerator was completed on schedule and well within budget. They tried to get it working, but the particles consistently failed to circulate in the miles-long stainless steel tube. The tube was a little larger than the diameter of a tennis ball and was normally pumped out to extract all the air so that the particles could circulate unimpeded. Was there a blockage? Had a workman left an object in the tube? How to find an obstruction in all those miles of tubing? Ask Bob, of course.

As predicted, Bob had a solution. In his part of Yorkshire, hunters used ferrets. Ferrets are weasel-like mammals who enjoy going down tunnels and flushing out rabbits. A ferret would not hesitate to run down the inside of the stainless steel tube, even if that involved a long journey into the unknown. Furthermore, it would be a sort of green solution to a technical problem, and everybody liked the idea of that. Bob was delegated to find and purchase a ferret and get instructions on its care and upkeep. It formed a talking point in the interval before its arrival. Suppose the ferret, instead of finding an obstruction, caused one by leaving droppings in the tube? Give it an aperient beforehand, perhaps?

The ferret arrived in a cage. They called her Felicia, and she soon won everyone over. The potential problem of the droppings was avoided by supplying Felicia with a diaper. Felicia was introduced to the stainless steel tube and went down it without hesitation. Hours later she emerged, looking a little tired and bemused but otherwise quite healthy. There was no obstruction.

The mathematicians found out why the particles had failed to circulate. It was something to do with the stability of the orbit, and the particles were crashing into the wall of the tube long before they completed their circular journey. They even found a solution, and they were able to pension off Felicia and relegate her to the position of laboratory pet and mascot. Bob escaped from the situation with his reputation intact. After all, he had furnished a solution to the problem as it had been put to him.

I wonder whether Felicia is still remembered at Fermilab?

Frank Beck is a retired CERN staff member living in England. He spent two years at the Fermilab as head of research services when the Energy Saver was being commissioned.

Editor’s note: For more about the pipe-cleaning ferret, have a look at various local newspaper accounts of Felicia recorded on the History and Archives Project website. Also check out a 1971 issue of The Village Crier. The Village Crier published an obituary of Felicia a year later.

My first year at Fermilab was 1968. I was a maintenance man when I first started, and we did all kinds of things in the early days: digging holes for trees, planting trees, shoveling snow, plowing snow, hauling garbage. We took care of furnaces, toilets, windows, window shades. We exchanged water bottles for drinking water, moved furniture, ran errands.

I worked on Robert Wilson’s car at times, which I enjoyed. We also did a lot of yard work out at Site 29. Wilson liked it clear, and we spent at least a good summer clearing the brush in the front of the house. There were lots of hawthorn trees in the front yard. The thorns in them would fall out, and our lawn tractor would get flat tires — constantly. So we made some steel wheels for the front of the tractor.

Our crew worked closely with Wilson. He was very charismatic, very friendly and outgoing. If he met you once, he remembered you by name. We’d have hot dog cookouts in our shop on Fridays, and our boss, George (I got called little George for forever), would always invite the directorate. They came over and had hot dogs with us, and we chatted.

I appreciated Wilson’s attitude toward the lab’s trees and landscaping. I was told you needed his permission to cut a tree down or even cut a limb from a tree. According to one story, Wilson moved the beam target areas because there was a group of trees at the targets’ planned location.

Wilson didn’t like things that reminded him of the war years. He didn’t like barbed wire. One of the early jobs I did was going around cutting barbed wire off the fences. He didn’t like fences, period, but particularly didn’t like barbed wire. In one case, right across from our office was a water tower with a fence around it and some barbed wire on top. I had to go cut that off. He wanted no part of it. Eventually, he took the fence and everything down. He also didn’t like trailers or Quonset huts – anything that was military-related. Word was he was just intense about that kind of thing.

As a director, he was completely geared to building an accelerator — very hands-on in that respect.

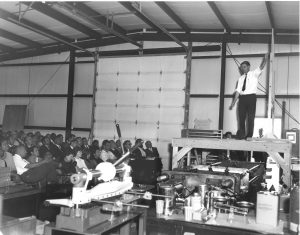

I vaguely remember the speech he gave in front of the old director’s complex. We were all standing out in the street. He said something to the effect that we had just received a few million dollars, and we were going to spend it all in the next couple of days so we could build our machine. That was his attitude.

He was building a laboratory, and we were going to build an accelerator — today.

The first office building for the National Accelerator Laboratory was in Oak Brook, Illinois. We occupied one floor of that high-rise building.

One day Robert Wilson decided that, instead of taking the elevator, he would climb 10 flights of stairs to work. Some of the rest of us followed his example, and then we got the idea that we’d see who could do it the fastest. Bob could get up there really quite quickly, and, as I was only 30 at the time, I took it as a challenge to see what I could do. It took a while, but eventually I was able to beat his time — about a minute. I called my wife and told her, in great excitement and very much out of breath, that I’d succeeded in a making a good run up the stairs. So did another one of the younger guys.

At the end of that year, 1967, the lab staff had finished the conceptual design report for the lab’s facilities and accelerators, and just as we were about to finish the day’s work, the power went off. A bulldozer had, in the course of aiding the construction of a new building next door, struck our power lines. People had to leave. There were many people from all building floors making their way down the pitch-dark stairways. I don’t know how anybody else did it, but I knew exactly how to get down. I ran down the stairs really fast — I knew the exact way to go!

1970s

It was in 1979. I was visiting the Fermilab on release from CERN, as a guest scientist, and enjoying the wonderful spirit of a young laboratory of world standing. It was a privilege, and my wife and I were able to rent a house on the site at Sauk Circle, right where the action was and conveniently near the various labs and workshops.

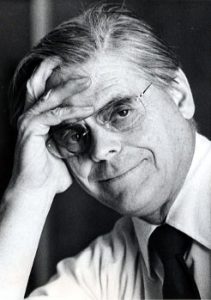

The director, Leon Lederman, had a house on the site too, and he and his wife Ellen had invited us to a dinner party one evening. On this occasion they had asked Leon’s secretary and a notable guest, Robert Wilson, the founder of the lab and Leon’s predecessor. Very exciting.

An interesting dinner guest was Professor Wilson. He regaled us with stories of the early days of the lab, and how he had juggled with his duties at the lab and his professorial responsibilities in Ithaca, New York, by commuting in chartered aircraft at least once a week.

He also told the story of the walnut trees, which I now repeat for the record.

Soon after the site was designated and taken over by the U.S. government, and before a security fence and checkpoints were in place, some thieves succeeded in cutting down several beautiful, mature walnut trees, the trunks of which they were clearly intending to collect and sell for a considerable sum. As it happens, they never returned to remove them for fear of apprehension now that their misdeed had been noticed.

Robert Rathbun Wilson was faced with a dilemma. Obviously this valuable resource, the property of the United States, had to be exploited for the benefit of its owners as efficiently as possible. After making inquiries, he discovered that because walnut was used to make veneer for fine furniture, these tree trunks were potentially very valuable. Thousands of dollars were involved. He decided to store the tree trunks as a budget reserve which would come in useful if he ever had to deal with a shortfall.

Three or four years later, the opportunity arose to use his timber nest egg. He then discovered what his informants had failed to tell him. The tree has to be reduced to veneer within a short time of felling. Disappointing. By now, it was just high-class furniture wood. Its potential as a source of veneer had been lost and its value was considerably lower.

He decided to make the best of it. The now seasoned timber would be used for the benefit of the newly constructed high-rise building.

And that is why the handrails in all the stairways of what is now called Wilson Hall are made of the very finest solid American Walnut.

Frank Beck is a retired CERN staff member living in England. He spent two years at the Fermilab as head of research services when the Energy Saver was being commissioned.

Editor’s note: Since posting this article, a couple of readers have chimed in with more information about the fate of the walnut trees. Some of the wood went into the construction of Ramsey Auditorium. Check out the History and Archives Project and a 1971 issue and a 1976 issue of The Village Crier (see page 2 in both). Read about the preservation of trees on the lab site and see a photo of the walnut trees from 1969 (here’s the 1969 newsletter). The same wood was used in 1981 to make the letters on the auditorium.

It was in the 1970s, and Fermilab was in the middle of its construction phase. Bob Sheldon had been called in to look for shortcuts and cheaper solutions to problems. Flush with the success of his suggestion to look for obstructions in the accelerator tube by using a ferret, Bob had decided to contribute more original ideas.

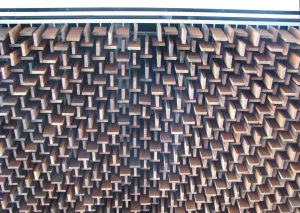

Professor Wilson was busy erecting large abstract sculptures on the site. Interesting shapes and striking colors were the order of the day. Bob saw the opportunity for another innovative idea when one of the outlying buildings on the site, which was to be a support facility for a large particle detector, needed a roof.

If the building had to have a roof, why not a spectacular one? Buckminster Fuller’s creations were in full swing at the time and all the rage. A geodesic dome, made of triangles eight feet on a side, would certainly keep the elements out and, if the triangles were double-walled, provide heat insulation too. He decided to make the elements of his dome of two strong sheets of transparent plastic, separated by a large number of strengthening elements. Why not make a honeycomb of sheet metal cylinders, retrieved from salvaged drink cans with their ends punched out?

He quickly devised a simple tool to reduce an empty pop can to a cylinder of sheet metal by removing the circular ends. Now he could find a suitable adhesive and make a prototype triangle to show that the scheme was practicable.

How to obtain the necessary recycled drink cans in the thousands that would be required? Easy. Get some publicity, and appeal to all the schoolchildren in the surrounding area to collect empty soda cans. They would get a good feeling by participating in a serious grown-up project, and the lab would get its roof much more cheaply.

There was a flaw in the argument, of course. Technically, it was a triumph. But the social element had a fatal flaw.

When news of the project got into the local press, it was picked up by a large soft drink company. It wasn’t long before the Fermilab directorate received an official offer to supply the necessary tens of thousands of cylinders free of charge, from an early stage in the production line and before the circular ends had been installed.

It was an offer they couldn’t refuse, and the schoolchildren’s efforts were no longer needed. So the roof was constructed, and it worked.

Frank Beck is a retired CERN staff member living in England. He spent two years at the Fermilab as head of research services when the Energy Saver was being commissioned.

Editor’s note: For more about the construction of the Geodesic Dome, see a collection of articles on the History and Archives Project website. You can also see photos of the roof before it was completed. It received a copper facelift in 1982.

Robert Wilson was a man born out of his time.

He lived in America from 1914 to 2000, but he really belonged to the central Italy of the 1500s. He knew this, but was determined to make the best of the opportunities afforded by the 20th century.

Robert Rathbun Wilson was a son of a small American township called Frontier, Wyoming, but while his intellectual brilliance and talents soon took him to many more interesting places, he never forgot or underestimated his roots in small-time America.

His academic success took him to California, where he studied physics to doctoral level, studying under Ernest O. Lawrence on the theory of the cyclotron. By the time the United States entered the war he was working with Robert Oppenheimer, who recruited him as a group leader at Los Alamos, where he contributed to the building of the first atomic bomb. He then retired to a more peaceful existence as a professor at Cornell University.

When in the 1960s United States decided to build the world’s largest particle accelerator, Robert Wilson was the obvious choice of a man to build it. A site was chosen on the prairie, 40 miles out of Chicago. Boring, flat farmland is not a very exciting place to attract the brains that would clearly be needed to man it.

Robert Wilson was up to the challenge. His own personality and reputation were sufficient to attract the talent he needed, and he soon had a small team of potential group leaders with the requisite skills.

The site, about 10 square miles in extent, comprised more than 50 farms whose owners had been reimbursed by the government, some woods and an old cemetery. Wilson had the clapboard houses moved physically to make a charming little artificial village, found a site for the accelerator, which was to be a circular structure about a mile across, designed and built a laboratory building 15 stories high, stocked the site with a herd of American bison and the lakes with trumpeter swans, arranged for some of the land to be turned from farming back to its original tall grass prairie, and covered the site with sufficient roads for access. Characteristically, the roads are named after the Indian tribes that once inhabited the area.

As well as being a scientist, he was a sculptor and an architecture enthusiast, and the design of the high-rise building bore his influence. He covered the site with large abstract sculptures of his own design. At one time he took a course in welding so that he could realize his own art work. One of the pieces was an obelisk, placed at the end of a reflecting pool situated in front of the high-rise laboratory building. He called it “Acqua alle funi.”

* * *

In the early 1500s, Bernini and Michelangelo were busy building and decorating St. Peter’s cathedral in Rome. Some years later, it was desired to re‑erect in the middle of the circular colonnade an enormous monumental pillar from antiquity that was there. The pillar, made from granite and weighing many tons, was to be brought to a vertical position and dropped into a prepared hole so that it would stand and occupy the most prominent position at the center of the most important piazza in the world.

Elaborate preparations were made for the raising. A huge wooden structure was erected, with pulleys and ropes enabling the column to be pulled up by the combined efforts of hundreds of workers. A day was set aside. Everything was ready for the effort. As an additional guarantee of success, the Pope decreed that no one was to speak while the work was in progress, so that the instructions of the overseer could be clearly heard. The penalty for speaking is variously reported as having been death or excommunication.

The work began. The workers toiled at the ropes, and the pillar began to rise. The hot Roman sun ascended in the sky. As the angle of the great stone obelisk increased, so did the temperature of the ropes. The energy expended by all those people pulling heated them, and the blazing sun did nothing to help. In due course they became so hot they began to smoke. If they caught fire, the obelisk would come crashing down. It might even shatter.

Photo: Staselnik

Photo: Staselnik

It was at this time that one of the workers, a Ligurian sailor called Bresca, decided that the rule of silence was less important than the success of the project. He shouted out: “Acqua alle funi,” meaning “water to the ropes.” The astounded overseer, realizing that this was useful advice, had water fetched and poured on the ropes. The project was saved. The obelisk adorns St. Peter’s Square to this day.

When it was reported to the Holy Father, he decided on clemency. The punishment was lifted, and the brave worker was rewarded. He and his heirs were given the privilege of a monopoly in the sale of palm leaves to pilgrims in St. Peter’s Square on Palm Sunday of each year. Apparently the family survives, and still enjoys the privilege.

Wilson erected his obelisk on the site of his laboratory in May 1978.

Frank Beck is a retired CERN staff member living in England. He spent two years at the Fermilab as head of research services when the Energy Saver was being commissioned.

Editor’s note: For more about the construction and installation of “Acqua Alle Funi,” including historic photos, check out the History and Archives Project website. A May 1978 FermiNews article (see page 2) reports on the sculpture installation.

Nearly every Friday at 4 p.m., Fermilab presents the Joint Experimental-Theoretical Physics Seminar. While there are many seminars and colloquia during a week at Fermilab, this particular seminar — also known as “the wine and cheese talk” for the refreshments that are traditionally served beforehand — is the lab’s principal venue for showing off new results in particle physics. Thus, it’s always well-attended, and a coveted venue for speakers.

But why have the most important seminar of the week late on a Friday afternoon? It can’t be convenient for a visiting speaker who wants to get back home for the weekend, nor for potential audience members who might have family commitments. Of all the days of the working week for an afternoon seminar, this might be the worst.

The scheduling of the wine and cheese seminar goes back deep in the history of the lab — all the way to founding director Robert Wilson. Before he came to the plains of Illinois, Wilson was the director of the Laboratory for Nuclear Studies at Cornell University, where I got my Ph.D. and learned the story of the Friday seminar from senior faculty members there. (I might be the youngest person in the world with an answer to this question.) Wilson created a working culture at Cornell that was all about getting things done. Major accelerator projects were built under budget and ahead of schedule, and then they ran all the time. (They even ran through the December holidays; I have happy memories on being on shift for Christmas Day.) Wilson famously brought this can-do culture with him to Fermilab, as we will be hearing more about during Fermilab’s 50th anniversary year.

One method that Wilson had to make sure that things got done was to incentivize people to work full days. And thus, the main particle physics seminar, the Laboratory of Nuclear Physics Journal Club, was held at 4:45 p.m. on Fridays. Wilson had a simple plan: Everyone was to work all through Friday afternoon for the reward of a seminar on an interesting physics topic, and perhaps also coffee and a donut. (For some graduate students, that donut was the main meal of the day, but that is a tale for another time.) And this same modus operandi was brought to Fermilab.

Now, a seminar that started at 4:45 p.m. could easily run until 6 p.m. That might have worked when Wilson was lab director at Cornell and the physicists at the lab were all men who, if they had families, most likely had wives tending to the house. In our modern times of greater (but admittedly not perfect) gender equality and more families with two working parents, such a late seminar is inconvenient. In the mid-1990s, my adviser undertook the delicate political task of getting the seminar time changed in the name of family friendliness. She succeeded, and there was much rejoicing. For the first ever 4 p.m. Journal Club, we celebrated by hanging streamers in the seminar room and buying a cake decorated with a clock that had its hands set to the new start time. (After the change, one emeritus professor at Cornell was overheard saying, “I can finally go out to a movie on a Friday night!”) Four p.m. is also the start time of the Fermilab wine and cheese seminar, and it seems a good compromise between a full work day and a good evening with family. (The Cornell seminar now starts at 3 p.m. — pretty radical!)

The Cornell seminar had two interesting rules that were passed down from its earliest days. One was that as soon as the clock hit 6 p.m., any and all audience members were allowed to leave, without any stigma, no matter where the speaker was in the presentation. Wilson apparently did have some limits. That worked well when the seminar started at 4:45, but once we moved the seminar to 4, we were never sure when a speaker had gone on too long.

The other one was that the presentation was not allowed to get “too theoretical.” Wilson had a simple metric for that: if the mathematical symbol γ5 appeared on the presentation slides, the speaker had crossed the line. (γ5 represents a product of Dirac matrices that, when used in quantum-mechanical amplitudes, indicates a parity-violating interaction.) Apparently Wilson would start berating the speaker whenever this occurred. I never saw this rule enforced when I was a graduate student (long after Wilson had retired), but on the rare occasion when a γ5 showed up on a slide, I would notice the more senior professors exchanging knowing glances, surely remembering how things were back in the day.

I don’t know if these rules have ever been enforced at Fermilab. But if you’re ever at the wine and cheese seminar late on a Friday afternoon, and the speaker shows a γ5, take a look around the room. If you notice someone rolling his eyes and checking the clock, then feel free to say hello to me after the seminar is over. As long as it’s before 6 p.m.

I used to feed the bison back in the day. We used to have two herds. One was where the current herd lives now, and the other was across the street. For that second herd, there were no trees or anything, so when the bison would shed their winter fur, they would rub against the fence posts to get the old fur off. They could actually destroy a fence. So a co-worker and I had to put up a scratch post, a big post with a big steel cable.

When we started setting up this post, the bison were way in the corner of the field. We’re sitting there working, and all of the sudden we heard this grunt. We look and the bull’s right there. Other bison are surrounding us. And I said to the other guy, “Let’s go.” He said, “Oh, they’re not going to mess with you.” I said, “I know, because I’m leaving. If you want to go, we can go.”

He didn’t want to go, so I got in the truck and left. They didn’t mess with him.

I’d seen how young bulls behaved before. Once a guy had left a tractor idling as we were going to lunch. The young bull was disturbed by it, and he kept charging it, and he finally hit it. He popped that tractor tire like it was a balloon. He almost knocked it over.

When I first started out here, in 1970, I worked with the farm crew. They had us going around cleaning out a lot of the barns after the farmers who were here on the land left. Hindsight being 20/20, there was a lot of really neat stuff that we threw away: We weren’t trying to preserve history or anything like that. We just wanted the barns cleaned out. For one, we needed a place to store the hay that we were growing for the buffalo.

That was some of the hardest work I ever did. We had a barn that we had stacked to the rafters with hay. But some of the baled hay hadn’t dried enough, and it spontaneously combusted. We came in the next day, and all that was left was the barn’s foundation.

I was also one of the people who cut the grass. It was more difficult than I had realized. The lab was just starting, and the equipment they had was just awful. The grass was very tall, and we had these push mowers. You’d go two feet and they’d clog up. It was similar with raking: They gave us garden rakes instead of a grass rakes. We finally got a riding mower that summer, and we were supposed to take turns using it. There were three guys that were messing around with it — fighting over it — and at some point they all bailed while it was running, and the mower ran into a tree. It was wrecked.

That was the first time I’d seen people get fired from the lab. They asked only a few of us to come back that summer. I was asked to come back, and I guess the rest is kind of history.

Sometime around 1973 I was the crew chief on shift for the Meson Lab. The electrical-power hand-off between the Accelerator Division and Meson Lab (part of the Research Division) was at the Meson Target Area, located between the MS-1 and MS-2 service buildings. MS-1 had power supplies belonging to each group.

A power supply failed in the MS-1 service building, which belonged to the Accelerator Division, and the Meson Lab would be down until it was fixed. After a fairly long wait, I drove down to the MS-1 area to talk to the Switchyard crew that was working on the power supply.

When I went in, I found a power supply scattered across the floor, but no one in the building. Just as I was about to leave, the door nearly flew off the hinges. In came Helen Edwards like a streak of lightning. She immediately asked in a very intimidating fashion, “What is taking so damn long to fix this supply?” I looked back and said, “I don’t know. When I see your guys I’ll ask!” Without missing a beat Helen asked, “Well who are you?”. I explained I was the Meson Crew chief, to which she responded, “Oh!”, turned around and left as fast as she came in.

Helen and I became good friends over the years, and when she moved into the office next to mine I reminded her of our early encounter, to which she said, “Yes, that sounds like me!” One of the many Fermilab friends I miss.

This shows the Meson Building under construction in 1972. Photo: Fermilab

This shows the Meson Building under construction in 1972. Photo: Fermilab

It was late 1972 and the Meson Lab was just working on its first beam transport. I was a new crew chief, having just joined the lab, and a man named John was my assistant. We were operating from the MS-2 service building with the roaring power supplies. It was about 8 p.m. The Main Ring had just gone down and the Main Control Room gave an estimate of one hour. (Everything only took one hour back then, until they gave the next updated estimate of one hour!)

As I sat and fiddled with the MAC-16 control computer to see what it would do, John sat with his feet propped up on a desk watching “The Honeymooners” TV show starring Jackie Gleason on a small black and white monitor. I looked up to see a gentleman walking towards me wearing a beret and wearing a top coat. He came over and asked what I was doing, and I said I was trying to learn all about the computer. Nowadays it would be called hacking!

I mentioned the ring was down for an hour. He thanked me, turned and walked back toward the door, glancing at John as he walked past. I asked John who the gentleman was, and John just shrugged. “No idea” he said.

When I came in for my shift the next day, my boss, Jim, called me in to his office. He looked at me with a terse smile and said, “Dr. Wilson was happy to see you trying to understand the control system, but for crying out loud, don’t let John watch “The Honeymooners” when the director is there!”

That event was my introduction to Dr. Robert R. Wilson, and I spoke with him numerous times after that.

Paul Czarapata is the deputy head of the Accelerator Division.

In the early 1970s, many of us were working lots of overtime, about 12-hour days. One time, I’d come to work at 6:30 a.m. Thursday morning, worked until 6 or 7 at night, and had just gotten home when I got a phone call: “We need your help.”

It was about DUSAF, the engineering firm that designed the Main Ring, Linac and other conventional facilities.

The DUSAF organization was moving out of their Hinsdale offices, and the mover they’d hired had gone on strike. I was told that DUSAF had to move out by midnight or pay major penalties from the office building they were renting. I was asked if I could grab a vehicle and go to Hinsdale with anybody I could find to help move their stuff out. Others had already been called.

I had a cousin who was working here at the time. I picked him up, and we went to Fermilab and picked up a step van. When we arrived in Hinsdale, a moving van was already loaded, but nobody was doing anything with it. We went into the building where lots of odds and ends were still in the office building. Many people had come to help. It was a madhouse. Everyone just walked in the building, grabbed whatever they could, brought it out, threw it in a truck and drove it to the laboratory. There wasn’t much packing. Whatever you could get in the truck, we moved. I made one trip. Once we got back to Fermilab, I stayed to help sort and unload throughout the night.

We worked all day that Friday, till 5 p.m. We finally got them moved out.

That was probably the most overtime I’d ever gotten in my life.

George Davidson is the head of transportation services at Fermilab.

Paintbrush

Back in 1972 or so, while I was a graduate student at Cornell University, fellow graduate student Steve Herb joined Fermilab experiment E-26. On one of his regular visits back to Cornell, Steve said that he was called into Fermilab Director Bob Wilson’s office. “What for?” I asked. Apparently Fermilab artist Angela Gonzales was not very happy about the green color that Steve had painted his toroid magnets.

Steve said that he could remove the windings that they had laboriously placed on the steel toroids, repaint and restore the windings. However, that would probably kink the windings, which would require the purchase of new copper cables. So he asked Bob whether he should do that.

Steve said that Bob replied something like, “Oh, it’s OK. But next time, before you pick up a paint brush, check with Angela first.”

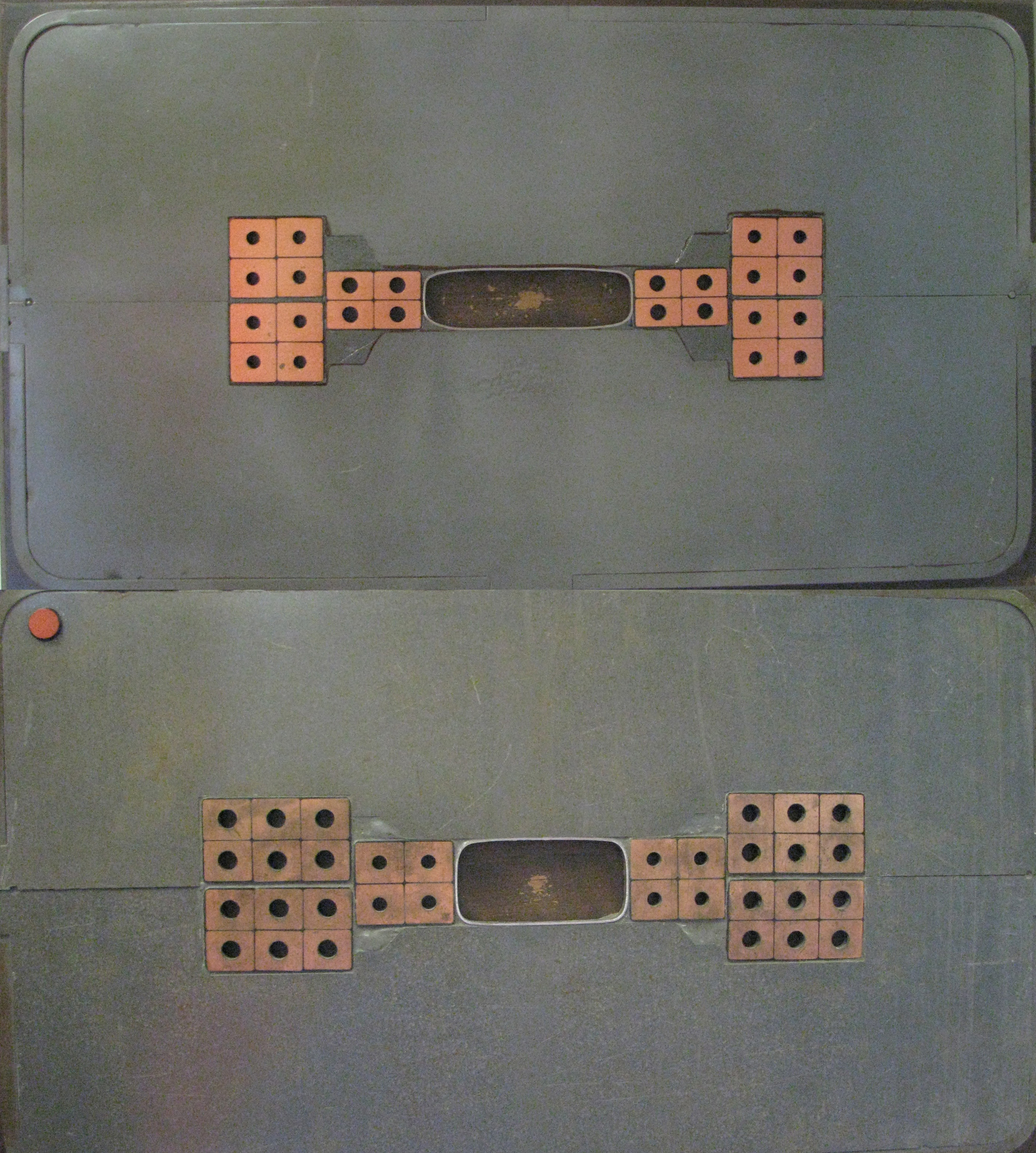

These are the magnets from E-26, which were mispainted green. Photo: Fermilab

These are the magnets from E-26, which were mispainted green. Photo: Fermilab

Viewpoint

In June 1978, Fermilab Director Bob Wilson’s sculpture “Broken Symmetry” was erected at the Pine Street entrance to Fermilab. I had been away on the day that it was erected, so later that evening my wife Jean and I walked in from our nearby home in Batavia to check it out.

Just as we approached “Broken Symmetry” from the west, Bob Wilson drove in from the east. He asked, “What do you think?” I said, “Pretty interesting … why did you paint it black?” Bob replied, “It’s not black, it’s orange.” Startled, I said “Say what?” Bob replied, “Come over here,” at which point I realized what he had done. I guess you just shouldn’t ask an artist “Why?”.

“Broken Symmetry” was under construction in 1978. Photo: Fermilab

A paint job

In 1983, as we prepared for the first beam from the Fermilab Tevatron, we refurbished and upgraded all of our facilities in the Fixed Target Experimental Areas. Although the Tevatron was to be capable of running at an energy of 800 GeV, the first few months of operations were to be limited to 400 GeV in order to finish off some experiments that were not to be upgraded to 800-GeV capability. I added a second dipole magnet to the single-dipole magnet in the Proton East primary beamline (my version of the Energy Doubler). In November 1983, a colleague was trying to tune the first Tevatron 400-GeV beam through these two dipoles in Proton East, without luck. The beam somehow got lost in those 40 feet of magnets. I walked into the control room and, using the beam loss monitors, was able to thread the beam through the two dipoles, but at 50 percent greater electrical current than expected. This indicated some sort of electrical short, which meant lower magnetic field and less bending. Since we had designed for 800-GeV operations, this extra current was within our tuning range at 400 GeV, at least for the short term.

During the next interruption of accelerator operations, that typically occur while commissioning a new machine, I accessed the Proton East beamline to see if I could determine what the problem was. Everything looked normal until I noticed that that the beam pipe on the upstream B2 dipole was a little wider (5 inches) than for the downstream B2 dipole (4 inches). “What the…!?!” One of those baby blue (NAL Blue Light) dipole magnets was really a B1 dipole, which should have been dark blue (NAL Blue Dark). The inner coils of the B1 and B2 dipoles are wired exactly opposite, so when the electricians saw the baby blue color, they had hooked up the B1 magnet as if it were a B2 magnet, thereby setting them up so that the two outer coils produced magnetic fields pointing upwards and the one inner coil produced a magnetic field pointing downward. This reduced the net field in that magnet, requiring more current to get the required beam bending. Once this was realized, it was an easy fix to reconfigure the connections for proper operation. With a Sharpie pen, I wrote on that miscolored magnet, “This is really a B1 magnet.” Yes, I should have noticed that error before beam arrived, but that level of subtlety was a little beyond normal.

The next workday, I discussed this with the engineer in charge of the beamline installations who said that earlier, in the shop, they had given a summer student a can of baby blue paint and told him to “paint those magnets,” not realizing that there was a B1 in among the B2s.

You’d be hard-pressed to tell the difference between these two types of magnets (B1 upper, B2 lower), which were both painted light blue, installed in the beam tunnel simply from the widths of their beam pipes.

You’d be hard-pressed to tell the difference between these two types of magnets (B1 upper, B2 lower), which were both painted light blue, installed in the beam tunnel simply from the widths of their beam pipes.

Peter Garbincius, in October 1976, was three months on the job and still on probation.

Back in the late 1970s, the experimental areas were organized into the Meson Lab, the Neutrino Lab and the Proton Lab. I was a young member of the Proton Lab walking down the hallway on the 11th floor of Wilson Hall when an administrative staff member handed me a telephone and asked me to please take this call. OK!

I listened patiently while the caller explained how a proton could be held together with hooks and springs. When he had finished his description, I asked why he was talking to me. He answered, “Well, you’re in charge of protons.” I had to agree, but then suggested that maybe he should be talking to the Theory Department.

His answer, “They transferred me to you.” I see… With friends like that…

Way back when, I was in the Materials Supply Group, I was in charge of looking through lists of equipment that laboratories and government facilities had placed in excess — things they no longer needed — and that could be transferred to another laboratory.

I had heard through my boss Norm Hill and other higher-ups that they were looking for a liquid-helium plant. They needed it to cool the magnets in the Main Ring and to do their experiments for the future Energy Doubler. So I was looking and, lo and behold, I came across an air separation plant. It was thousands and thousands of dollars. We acquired the Worthington reciprocating compressors that were used in the plant.

We worked it out with Norm Hill and Jack Jaeger, the directorate approved it, and it was all free of charge. All we had to do was pay the shipping. It was a pretty huge acquisition. It was from a facility in California.

The compressors arrived in pieces on big flatbed trucks — huge trailer-type vehicles.

People were so happy to get it free of charge. I saved the lab mega bucks.

You can read about the liquid-helium plant in the Dec. 11, 1975, issue of FermiNews, page 1.

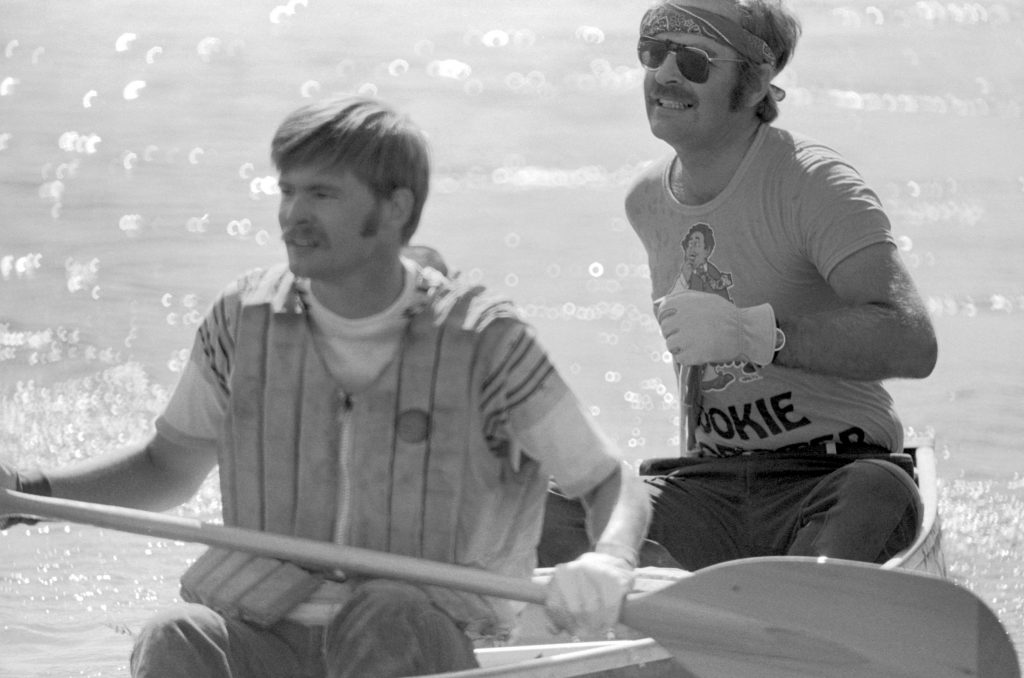

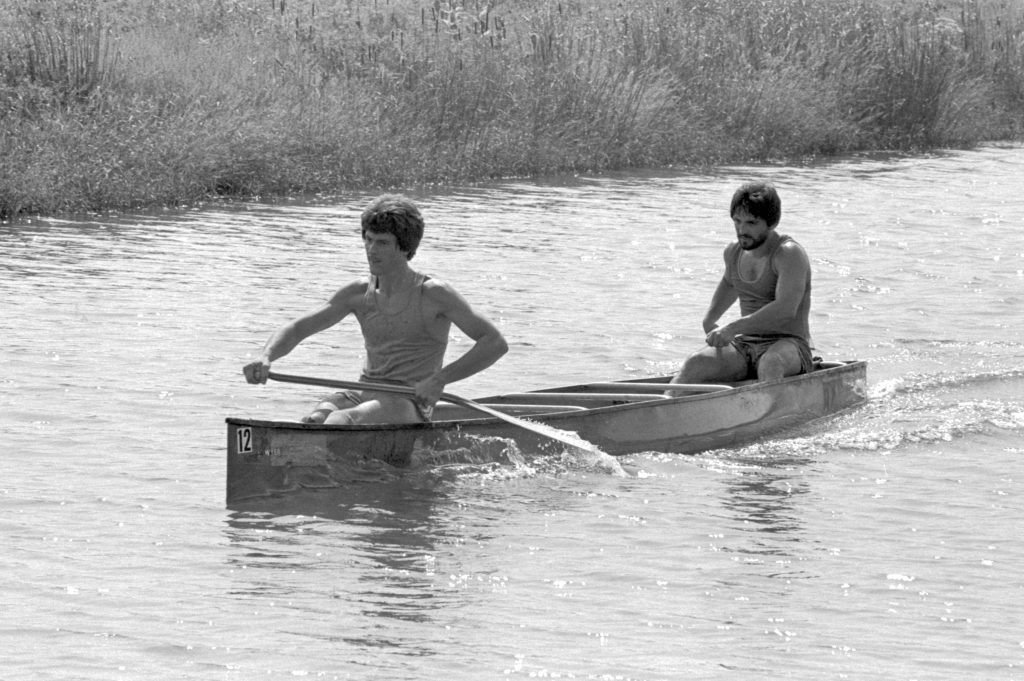

Sept. 30, 1979, about 1:45 p.m.: SNAP!! @#@#@#@!!! Gerd Hartner, in the bow of his canoe at the race starting position, dipped his paddle in the water, gave a mighty first pull and, to his astonishment, broke it in half. Hilarity ensued among the cheering onlookers. Recovering quickly from the shock, Gerd was handed a replacement paddle so he and teammate David McFarlane in the stern could start again.

This was one of the more bizarre happenings at the once-upon-a-time annual Fermilab Canoe Race around the cooling ponds of the 4-mile Main Ring particle accelerator. The race was one of the most exciting extracurricular competitions in the history of physics labs and was held on a weekend in early autumn for a few years starting in 1974. The event was founded and organized by Larry Allen, an operations specialist, with help from other employees and the Amateur Radio Club (egad, the dark ages before cell phones) for communications around the ring to monitor mishaps. The race was a time trial, with each of about a dozen canoes setting off at three minute intervals. Crowds (not large!) of spectators showed up, pizza and beer were provided afterwards, and trophies were presented to the winners.

In 1975, John O’Meara and his daughter Sue placed third, with their time of 63 minutes, 16 seconds. Photo: Fermilab

In 1976, Jim Prentice and John Martin came in second place, with a time of 48:06. Photo: Fermilab

It was a grueling experience. Paddling flat out for about an hour is hard enough, but the course is interrupted by 17 exhausting portages up and around the dikes through long prairie grass and much soft mud. Competitors included university and lab physicists, graduate students, engineers and other staff members, both men and women. Some had more enthusiasm than expertise — in one race I passed a team going the wrong way desperately trying to turn their canoe back to the right direction. Often people got soaked and muddied along the way and plunged into the water after the finish line to clean up and cool off.

Canadians, of course, were overrepresented. As well as hockey, canoeing is in our DNA, so we were determined to win or at least place highly to avoid embarrassment. I won two of the races (with bowmen Jim Prentice and Bob Sheperd) and came second in another four (with Mike Shaevitz, Dale Pitman and Jim Prentice). However, the outstanding Canadian was my colleague George Luste, who won often and set an early record of 45 minutes, 19 seconds in 1976 with bowman John Cumalat. That year the four of us physicists in the first two canoes were all from experiment E25. Based on this showing of strength, we asked for more beam time, to no avail as I recall…

For the 1976 race, Chair Larry Allen draws the entering order for the 12 participating teams. Photo: Fermilab

John Cumulat and George Luste won the second straight Main Ring Canoe Race in 1978. They’d won the last four-mile paddle held in 1976. Their 1978 time was 49:33. Photo: Fermilab

The 1976 record was finally broken in 1980 by the powerful team of Steve Conlan and David Carlson in a racing canoe with professional paddles. They clocked “an astonishing time of 41:17.” As far as I can tell from the Fermilab archives, this was the last time the race was held. That year George paddled with B.J. Bjorken and came in sixth.

George is a legendary figure in North American wilderness canoeing circles, having paddled all of the great rivers, and most of the rest, in northern Canada over his lifetime, but that is another story (if interested, Google “George Luste canoe”). Sadly, he died of brain cancer in 2015.

Weary, wet and shoeless, a competitor climbs ashore at the 1979 finish line. Photo: Fermilab

On Sept. 20, 1980, David Carlson and Steve Conlon set a new world record in Fermilab’s Main Ring Canoe Race, demolishing the old record of 45:19 with the astonishing time of 41:17. Photo: Fermilab

The only year I beat George was in 1979 (he could not participate the other year I won). He used a racing canoe, which gave him a bit of an advantage over the rest of us in aluminum clunkers, but he handicapped himself by inviting the new director, Leon Lederman, to be his bowman. Leon got a shoe stuck in the mud on one of the portages and spent valuable time retrieving it, worried he and George might be disqualified if he came to to the finish line only half-shoed. According to FermiNews at the time, he claimed the difference between his time and mine was “statistically insignificant.” I suppose we would have to repeat the race many times over to prove him wrong!

On that note I encourage Fermilab to think about restarting this canoe racing tradition, since the Main Ring cooling pond course is unique in the world. Perhaps a separate kayak race could be included or even a paddleboard race (how about a kite-surfing race on a windy day? — that would be interesting, participants flying over portages, etc…). The canoe races were great fun and helped relieve some of the stress of carrying out the great physics mission of the laboratory.

John Martin, a former Fermilab user who collaborated on E25, E531, E516 and E691, is a professor emeritus at the University of Toronto.

For more on the Fermilab Canoe Races, see older issues of FermiNews: Oct. 10, 1974, p. 3; Oct. 2, 1975, pp. 1-2; Oct. 8, 1976, pp. 1-2; Sept. 28, 1978, p. 4; Oct. 11, 1979, p. 3; Sept. 25, 1980, p. 3.

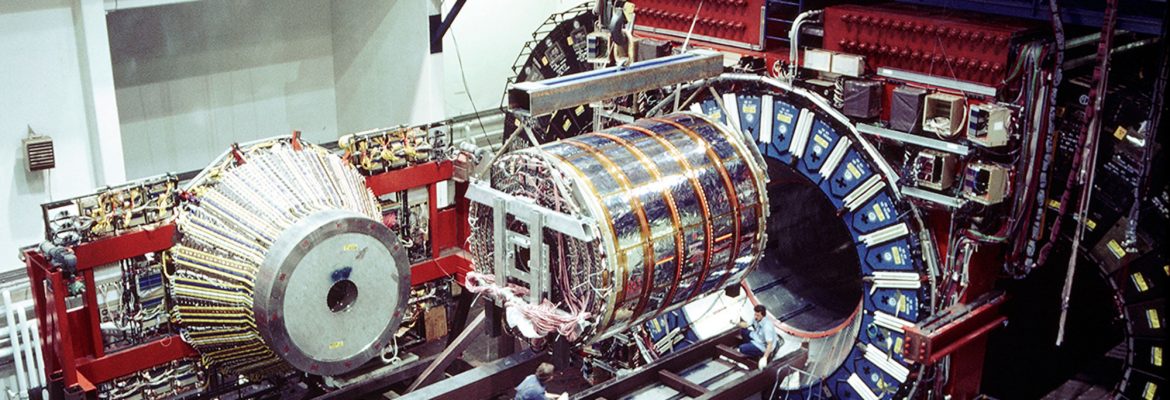

When I started at the lab in December 1977, work on the dipole magnets for the Tevatron was well under way in what was then called the Energy Doubler Department in the Technical Services Section.

My first project was to work on the quadrupole magnets and spools, which hadn’t really been started yet. The spool is a special unit that attaches to each quadrupole and the adjacent dipole. It contains what we used to call “the stuff that wouldn’t fit anywhere else” – correction magnets and their power leads, quench stoppers to dump the energy from all the magnets, beam position monitors, relief valves, things like that.

At the time, we were located in the Village in the old director’s complex, which now houses the daycare center. We had a large open area where the engineers, designers and drafters worked and a small conference room where we kept up-to-date models of some of the things we were working on.

For several weeks we worked feverishly on the design of the quadrupole and spool combination — we in the design room and the model makers in the model shop on their full-scale models. We would work all week, then have a meeting with the lab director, Bob Wilson. Dr. Wilson would come out to see how we were doing, but more importantly to see what our designs looked like.

It turns out he was very interested in that and very fussy that things — even those buried in the tunnel — looked just so.

After every one of those meetings we’d walk back into the design room and tell everyone to tear up what we’d been working on and start over. The same would hold for the model makers. This went on for several weeks until Dr. Wilson was happy. We began to really dread going into those meetings, but in the end they served us very well.

Where’d you go, missing block? Or were you ever there? (Do you see it?)

As you walk down the stairs from the main floor of Wilson Hall (cafeteria area) to the auditorium lobby, look up to the near edge of the wood block ceiling. Slightly west of the center line is a “hole” where a wooden block supposedly should be. I have often observed this hole since the ceiling was finished about 1973 and can attest that a block has been missing ever since. (Over time a few other distant pieces have gotten lost but should not be confused with this one.)

For me this has raised two issues:

- Was this just a mistake in assembling the structure and never corrected or

- Was this done on purpose to destroy any symmetry that might exist in this ceiling?

Obviously, the first issue is trivial except that it gives a plausible alternative to the second issue which is certainly more intriguing.

Fermilab founding director Bob Wilson appreciated the concept of “Broken Symmetry.” He designed a sculpture with this name, and it stands at the Pine Street entrance to the laboratory. He also gave a conference dinner talk, “Symmetry in Art and Science.” In it he discussed an artist dilemma of making something too perfect: “Only the gods are perfect.” Therefore ancient Asian artists would leave a small flaw in their work, he said. Did Wilson do the same here? I guess we will never know but the possibility is interesting.

Or, is it an omen of missing pieces in our physics knowledge?

Note: The wood for this ceiling and supposedly throughout the auditorium is walnut. It was gotten from several walnut trees that were cut down by vandals during the very early days of NAL. They were soon after captured by the FBI and the wood recovered. See the Fermilab history website.

Charles Schmidt is a Fermilab scientist emeritus.

This aerial view shows the Main Ring in 1970. Photo: Fermilab

This aerial view shows the Main Ring in 1970. Photo: Fermilab

It was the spring of 1967. The scene was a vast stretch of cornfields that were at one time the Illinois prairie, where many bison roamed. There stood the newly elected director of National Accelerator Laboratory, Bob Wilson. Born in Frontier, Wyoming, Wilson was filled with a pioneering spirit, both in science and humanity. He stood there with a vision of a 200-billion-electronvolt proton synchrotron, the world’s largest particle accelerator, up and running there in less than five years, a task that he was going to accomplish with a budget of $250 million.

Bob Wilson himself drew up the basic design of the magnets of the Main Ring — the 4-mile, circular accelerator that would ramp up particles to the desired energy. For the sake of economy, he would settle on an unconventional and extremely compact, but still functional, mechanical and magnetic structure. The insulation of the conductor was Epoxy-impregnated glass fiber, only approximately 2 millimeters thick. I worked on the detailed design of the dipole magnet, not just for operation at energies of 200 to 400 billion electronvolts, or BeV, but also to be operable up to 500 BeV. For these calculations I used the Argonne National Laboratory’s largest IBM machine to its full capacity of 2 to 4 megabytes over many weekends. I also designed and constructed the correction dipoles and the Main Ring beam detection system. John Schivel worked on the quadrupole magnet design.

The construction of the Main Ring magnets then proceeded at breakneck speed. We produced 774 dipole magnets — which steer the particle beam — and 240 quadrupole magnets — which focus the beam — as well as some extra spares in time for installation. We began installing the magnets into the Main Ring tunnel during the severe, cold of the winter of 1970 and through the following spring, when the air inside the tunnel was quite humid. It was the worst condition for magnet installation. The last magnet was installed in the tunnel on April 16, 1971.

The revolutionary and digital solid-state power supply, using thyristors and the power grid line, was designed by Dick Cassel and was implemented by his group, including Howard Pfeffer.

An unexpected crisis

On Feb. 26, 1971, we enthusiastically began the beam injection study into the Main Ring, as soon as the sector A, one-sixth of the whole ring, was available; we did not want to wait for all magnets to be installed. We could lead the injected beam through the whole of Sector A with one day’s operation. This was a rather easy job.

While we were continuing the injection study, on April 22, six days after the installation of the final magnet, we found that two magnets were shorted to ground. The ground insulation of the coil was broken, and we could not continue the operation.

Even though we had discussed the remote possibility of shorting of a magnet due to radiation damage, which might cause the eventual degradation of the thin Epoxy-impregnated glass fiber insulation layer, this came as a great shock for the Main Ring Magnet group.

“Now what can we do?” We decided that the physicists would continue testing the Main Ring with the injection beam during the night, while the engineers and technicians replaced the shorted Main Ring magnets during the day.

Wilson Hall is named for founding director Robert Wilson. The title of the obelisk, “Acqua Alle Funi,” means “water to the ropes” and was Wilson’s courageous advice to those building the Main Ring. Photo: Reidar Hahn

Wilson Hall is named for founding director Robert Wilson. The title of the obelisk, “Acqua Alle Funi,” means “water to the ropes” and was Wilson’s courageous advice to those building the Main Ring. Photo: Reidar Hahn

The physicists usually worked two shifts: the night and the midnight shifts. Sometimes they took three shifts. I usually took the night shifts. We ran the Main Ring continually, even over the weekends. For this reason, we brought in two beds into the basement room, under the Main Control Room. At some point, I started having pain in my neck and could not turn my head. For a while, there was a nurse standing in the back of the control room during the night shift.

The atmosphere in the control room changed from very strong optimism to ordinary optimism. The primary questions were: Why were the magnets shorting? How we could fix the damaged magnets quickly enough? Underlying it all was the concern: How soon could we achieve a circulating beam and eventually attain 200 BeV?

During a six-month period, from the start of the Main Ring beam injection in February to July, approximately 350 Main Ring magnets out of a total of 1,014 were replaced. That came to an average rate two magnets per day. The shorting and replacing of magnets continued afterward, and roughly half of them were replaced over two years.

Bob Wilson often visited us in the control room late at night. On one occasion, he wanted to try to tune the Main Ring beam himself. On another occasion, he brought in a book and started reading loudly from it in the control room. To me it was all Greek, but it turned out to be Italian. After reading it, he explained it to me that it was “Acqua alle funi.” It was what we needed at that time — intelligent and courageous advice: “Water to the ropes!”

A few days later, he visited me again in the control room and told me, “Ryuji, we may have to close the lab. Although I asked you to come and work with me on this project, I’m sorry, I may have to close the lab and ask you to go back to Japan.”

In reality, this was a common opinion outside of Fermilab during this crisis period. Many West Coast physicists were very tough on Bob, and many East Coast physicists had similar opinions. Before Bob Wilson was elected as the director of the National Accelerator Laboratory, there had been a solid 200-BeV proposal published by the Berkeley group. But Bob Wilson was nominated as the director on the strength of his drastically simplified, economical and superior plan.

Even inside Fermilab there were some pessimistic staff who had little hopes for the success of the Main Ring.

First one turn, then another: observing the emergence of life in the Main Ring magnets

For 10 days starting June 24, we were lucky enough to have 180 hours to concentrate on the Main Ring injection study. Although I had installed the position-sensitive electrical pickups around the ring, they were not yet connected to the control room.

But all correction dipole magnets were controllable from the control room. So one shift person had to stay in the control room, and the other shift person had to go around the ring on a truck, carrying an oscilloscope, and had to communicate with the operator in the control room by a telephone.

Therefore this was a cumulative effort from shift to shift and day to day. Many physicists were involved for this operation, including Helen and Don Edwards, Ernie Malumud, Ryuji Yamada, David Sutter, Chuck Schmidt, Sigeki Mori, Frank Cole and Al Maschke.

On June 29, 1971, Chuck Schmidt was in the control room. Al Maschke was going around the service buildings, while Dick Cassel was on shift for power supply. With the instruction from Al, Chuck was adjusting the correction magnets, steering the beam for the next service building. They worked for a long run. At midnight of June 30, we started our shift, continuing the same procedure. Around 7 a.m., we succeeded in getting the first turn of beam around the Main Ring, achieving the first goal. Soon the next shift, by Shigeki More, started. Together with the people who had congregated in the control room — including Bob Wilson, Deputy Director Ned Goldwasser and Ernie Malumud — we celebrated without any drink.

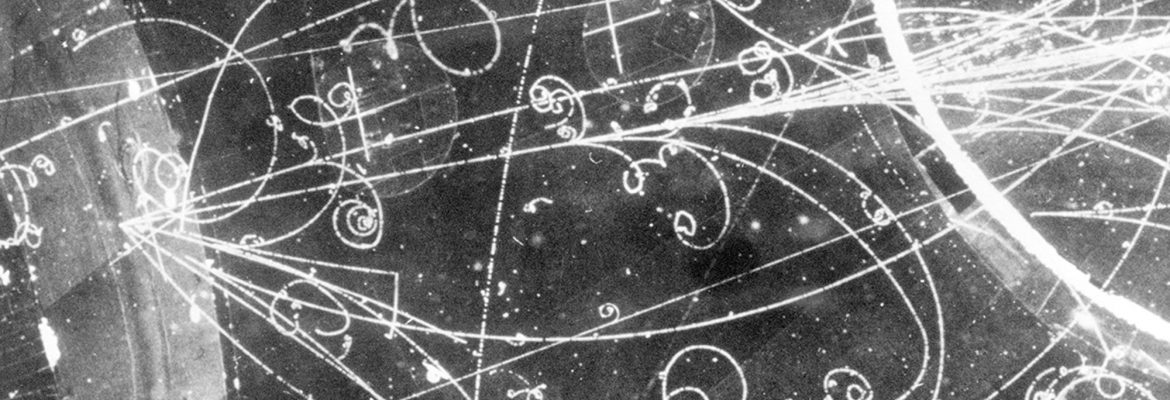

It was a first excitement for the people at that place at that time. Now we could see a faint second light spot on the meshed fluorescent target at the injection point. It was really dancing on the screen due to the fluctuation of magnet current. And on the special intensity beam monitor of my own design, we could see a clear second pulse 21 microseconds later, although much attenuated.

On the night of July 2, 1971, I was on shift, and we achieved up to eight turns around the ring of the injected beam. Again this helped us to gain back more confidence. In order to see the multiturn circulation beam as well as the injected beam, we had to remove all meshed targets. Now we could see the clear, sequenced but decaying signal pulses 21 microseconds apart on my detector.

“Sure enough, the Main Ring is working. It is not dead. It shows sign of life!!”

After the Fourth of July holiday came days of replacement and improvements of a series of magnets. On Aug. 2, 1971, Shigeki Mori took the shift for injection study, and we attained a coasting beam that went over 10,000 turns.

We then thought we could start accelerating the beam. But when we accelerated the beam up by 0.5 BeV above the injection energy of 7 BeV, we hit a brick wall. All the physicists desperately started going around the tunnel trying to solve the problem.

Another obstacle

A group of physicists, headed by Drasko Jovanovic, started installing simple radiation monitor cans around the ring to find the problematic location. But they could not find any localized trouble spots. Rather, they found that the trouble spots were all around the ring.

Then I thought of the damaging possibility of stainless steel slivers. These slivers were made when we changed the shorted magnet by cutting open the round welded vacuum pipe at the end of a magnet. When a new magnet was installed, some of the slivers were left inside unintentionally. So when the magnets were excited to a higher field, they were pulled inside the magnet gap, stood up and stopped the beam, because they were slightly magnetic material. (The detailed story is described in the Oct. 10, 2016, news story “Japanese influence a steady source of innovation at Fermilab.”

The next big question became, How we could clean these slivers, scattered throughout the Main Ring, after having replaced over 300 magnets already? I proposed pulling a permanent magnet through the vacuum pipes. The following question was, “How?”

Then an English engineer, Bob Sheldon, said, “In England, we use a ferret to hunt rabbits in small but long underground holes.” We thus obtained a ferret named Felicia. Unfortunately, she refused to go inside the small, dark metallic hole. (Later on, however, she helped us with a larger beam pipe.)

Hans Kautzky then had a brilliant idea. He suggested using the principle of a blow gun. He made a dozen Mylar disks, shaped to different shapes of the vacuum pipes. He then attached them in sequence on a stainless rod and added a very flexible stainless cable. Then he inserted the assembly into a vacuum pipe in a sector of the Main Ring and pushed it with compressed air from one end. It flew through the vacuum pipe easily. We were thus able to put a 700-meter-long cable through the vacuum pipe. Using this cable, we pulled a harness with a permanent magnet. With 12 operations, we could make it around the entire ring. This way we could clean the whole vacuum pipe, though not perfectly. This operation took about a whole month.

(There were many reasons for a magnet shorting. The main reason was poor quality control in making joints for the water-cooled copper conductors. The mating surfaces of a butt weld joint were sometimes not completely parallel, and the resulting joint might have a small, wedge-shaped gap. Later, improved welding with an inserted pipe was used.)

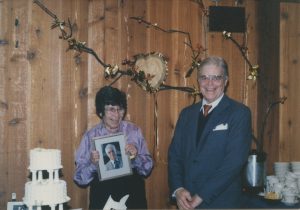

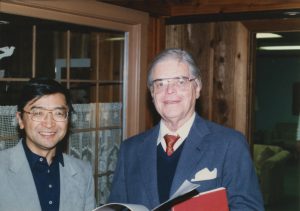

Jane Wilson holds up her husband’s picture on his 80th-birthday party. Photo courtesy of Ryuji Yamada

Jane Wilson holds up her husband’s picture on his 80th-birthday party. Photo courtesy of Ryuji Yamada

Acceleration to 100 BeV and 200 BeV

After cleaning the Main Ring vacuum tubes, we could accelerate the Main Ring beam steadily up to 20 BeV. On Jan. 22, 1972, we had a stable 20-BeV beam from pulse to pulse. Jim Griffin was working on the Main Ring radio-frequency system in the F Service Building.

We did not have any serious problem going over the transition energy of 17.4 BeV. On Feb. 4, 1972, we achieved 53-BeV beam. And on Feb. 11, 1972, we got 100-BeV beam, surpassing the Russian’s world record of 76 BeV.

During this period, Don and Helen Edwards fixed the tracking problem between the dipole and quadruple magnet power supply.

On March 1, 1972, Frank Cole was the captain of operations, and I was the co-captain. On these days, we were testing the Main Ring magnets without cooling water to avoid possible shorting of the magnets. We were running the magnet in the “two-mode operation:” 25 short pulses of up to 30 BeV for beam tuning, followed by a 200-BeV pulse, as suggested by Ernie Malamud.

When the beam trace on the scope crossed 100-BeV line, I called into the control room Director Bob Wilson and others were waiting in the next room.

Ryuji Yamada and Robert Wilson got a chance to chat about old times at Wilson’s 80th-birthday party. Photo courtesy of Ryuji Yamada

Ryuji Yamada and Robert Wilson got a chance to chat about old times at Wilson’s 80th-birthday party. Photo courtesy of Ryuji Yamada

Soon the beam trace hit the 200-BeV line — at 1 p.m. on March 1, 1972.

A wellspring of emotion erupted in the room. Congratulations were exchanged among all present. Bob Wilson and his gathered crew had been waiting for this moment.

Then all of sudden, boxes of champagne showed up, and Bob started pouring champagne for everybody present.

On March 3, 1994, we had an 80-year birthday celebration for Bob Wilson in the Fermilab Village. At the end of this party, Bob and I sat in a quiet corner to talk. He told me, “Ryuji, you really saved the lab. You were a hero. Thank you.” I believe that he really intended his thanks for the entire Main Ring group, as well as for all of Fermilab.

Bob Wilson’s ashes are buried in the old Pioneer Cemetery on the Fermilab site. When Mrs. Jane Wilson died later, her relics were buried next to his.

1980s

I think I can tell this now because I’m pretty sure the statute of limitations has expired. Around a year after I joined Fermilab, in the spring of 1992 or 1993, I got into the habit of a lunch time walk on the Ring Road with John Isenhour, who had come here a year or two earlier. John’s job was to manage the library VAX (yes, the library had its own little DEC VAX at fnlib.fnal.gov). In warm weather it was nice to go outside for a few minutes and get a little sun and fresh air.

On one of those days we were just getting started when John saw a big white tanker trailer used for liquid-nitrogen parked next to the A-1 service building on Main Ring Road. It had an open spigot and it was dumping liquid nitrogen on the ground. No one else was around and we had no idea why that was being done, but John put on a pair of gloves he happened to have and found an empty metal coffee can lying on the ground. Holding it under the tank tap by the top edge, he managed to get a quart of liquid nitrogen.

With it boiling away, we walked back into the high-rise. I had some initial misgivings about this, but those evaporated with the nitrogen while we talked of hammering nails with bananas and all the other fun stuff you can do with a very cold liquid. We got on a west side elevator and rode it to the third floor and walked out into the middle of the library, where we proceeded to play around with what was left. By then it was all gone, after only a few minutes, and before we (fortunately) could do much with it.

What mildly amazes me now is how at the time, this seemed like a typical Fermilab thing to do — have fun with unusual states of matter if given the opportunity. I have not been here 50 years, so I can’t be certain about this, but I bet this was the only time a cryogenic liquid was in the Fermilab Library.

I first came to Fermilab in January 1989, when I was a first-year student at The University of Chicago. I had just finished my first quarter of introductory honors physics, which was taught by Henry Frisch. Occasionally he had mentioned to the class that he did research at Fermilab, and there was a memorable day when he taught at 9:30 a.m. after being on shift overnight, but beyond that I knew essentially nothing about the lab. For reasons that I still don’t know, Henry offered me a job as an undergraduate researcher in his group when the course was over. On my first day on the job, he needed to find something for me to do. I was quickly spun off to graduate student Aaron Roodman, who was trying to track down the extent of the effect of a fault in the CDF trigger. This would require processing a bunch of data files at Fermilab, which thus required an account on FNALD, the VAX computer that CDF had for itself at Fermilab.

Today you can get a Fermilab computing account by filling out a web form identifying yourself, your affiliation and a Fermilab point of contact. But in 1989, you had to physically appear at Fermilab and register as a user on paper. And thus we found a day for me to drive with Henry from Hyde Park to the lab. Was there anything I needed to bring with me as a first-time visitor? “I don’t know how long we’re going to be there,” said Henry. “Maybe a change of underwear.” I was pretty sure he was kidding, but on the appointed morning, I did have a pair of underwear in my backpack, just in case.

My memories of that first visit are a bit vague. I don’t think I was expecting the modest front entrance, the wide-open prairie spaces or the bison herd. Even though I didn’t have much to do (as someone who had just gotten a computing account and didn’t really know what to do with it), I did spend the whole day there, as I had to wait to get a ride back home. (I ended up going back with Claudio Campagnari in Paul Tipton’s car; Claudio and I are currently collaborators on CMS.) While at the lab, I did attend a CDF data analysis meeting, which I didn’t understand at all, but which I later realized had one of the first presentations showing that B mesons could be constructed at CDF; this was never in the original physics program for the experiment and was a testament to the flexibility of the hadron collider program and the creativity of particle physicists.

But I remember that I returned to the dorm at the end of the day with my first Fermilab ID card, which identified me as user 5022V. I spent a lot of time that evening looking at it. There it was, a physical manifestation of my identity as a particle physicist — even though I didn’t think of myself as a particle physicist, and I couldn’t have known that this would be part of my identity for the rest of my life.

I have held a Fermilab ID card ever since — through my undergraduate years on CDF analyzing Run 0 data, as a postdoc at Johns Hopkins University and then the University of Michigan working on CDF during Run 2 of the Tevatron, and since 2004 as a professor at the University of Nebraska-Lincoln working on DZero and then CMS. My Fermilab ID identifies me as part of a community that is now 50 years old, a community of scientists that has grown to be international, spanning all aspects of particle physics, that has pride in its achievements and contributions to society and great hope for what the future will bring. I have always been honored to be associated with Fermilab and my fellow Fermilab ID carriers — and I’ve always been comforted in the knowledge that if my ID card is found it can be dropped in any U.S. Mail Box and returned to Box 500, Batavia IL 60510, postage guaranteed.

Strictly speaking, I was not a user from 1992 to 1997, when I was a graduate student at Cornell working at the synchrotron there. But throughout that time I carried my previous Fermilab ID card in my wallet, as if it were some kind of good-luck charm. When I returned to Fermilab in 1997 and renewed my user status, no one had asked me what had become of the previous expired ID. And thus I still have it in my wallet — a memory of my younger days, of the start of my career in particle physics and of our country’s flagship particle physics laboratory.

In the 1980s I’d joined the NAL Recreation Committee, or NALREC. It was a lot of fun. We’d host steak fries, sometimes charging people for food based on their seniority at the lab. We’d also host picnics in the Village. Everybody volunteered, and it was wonderfully family-oriented. We had kids, kids’ games, bands, DJs, horses, Ferris wheels. We also had a beer truck come in.

We’d bring out the dunk tank at the picnic. The tank wasn’t the best in the world, so I did some negotiating with different division and sections and managed to beg, borrow and find materials to make a new one. I picked up an old trailer from Roads and Grounds and persuaded the weld shop into welding the trailer, steel and unistrut together. Then I had some summer students help paint it. The tank had two stalls, and it came out pretty well. I and a number of helpers ran the dunk tank for several years as part of the NALREC contributions.

For those unfamiliar with a dunk tank: It’s a mechanism for good-humored humiliation. A volunteer (the humiliatee) steps inside the tank, which is partially filled with water. He sits on a small platform situated a short distance above the water and attached to a lever that, when pushed, releases the platform, causing the poor volunteer to fall into the water.

The typical method for pushing the lever is for a second volunteer — perhaps someone with a bone to pick — to throw a ball at it.

We managed to talk one particular gentleman to get into the dunk tank. He was a favorite to dunk. When people saw that he was the dunkee, we got a line 200 feet long queuing up to throw that ball. The end of the lever had a paddle about four or five inches around, but for this individual, I made a bigger one, clamped to the end. It was about a foot around. He got mad at me. But it went well.

Other VIPs got in the dunk tank, too.

You can have a look at the rebuilt dunk tank that George Davidson helped construct in a 1991 article from FermiNews (see page 4). For pictures of the earlier dunk tank and Fermilab picnics (including one of Leon Lederman in the tank), see page 2 of this 1980 issue and page 4 of this 1984 issue of FermiNews.

[fnal_accordion]

1990s

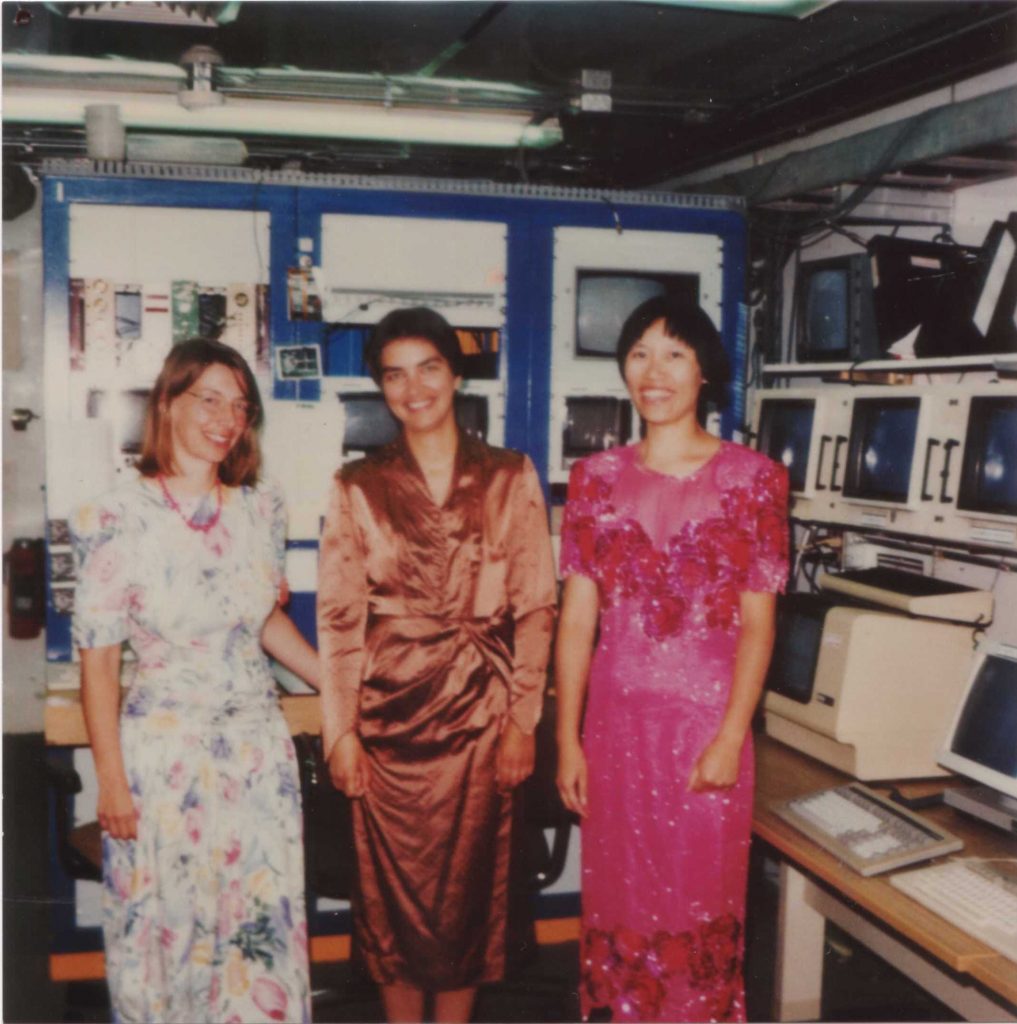

In 1990, Penny Kasper, Danying Yi and I were all graduate students on the E791 experiment. Part of the detector, controls and data acquisition system had been modified from the previous experiment, E769, so everything had to be tested before we got the first beams.

Jean Slaughter, who was in charge of the day-to-day operation of the experiment, announced we would have a “dress rehearsal.” Being a non-native English speaker, I had no clue what that meant. I asked Jean what would I have to do. She simply replied: “Just stand there and look pretty.” So I decided to take it literally and convinced Penny and Danying to join in.

Just before the dress rehearsal, we all snuck out and came back to the control room dressed to the nines. Penny wore her best dress, Danying put on the special wedding dress her mother had sent her from China (hoping to encourage her to get married), and I wore my mother’s copper satin wedding dress.

When we showed up in the control room, our colleagues all looked puzzled. Most had a great laugh, even though I suspect many of them just thought we were plain nuts.

Pauline Gagnon was a scientist at CERN and a member of CERN’s communication group. She is the author of a popular science book on particle physics, “Who Cares about Particle Physics: Making Sense of the Higgs Boson, the Large Hadron Collider and CERN.”

One summer I was working under the supervision of Marleigh Sheaff, who was a user at University of Wisconsin–Madison. We were doing some calibration work with transition radiation detectors. We worked in the Tagged Photon Lab, and for whatever reason, it was exciting to get the key to open up the enclosure and go inside. There were snakes, dead spiders and squirrels in the old beamline where E769 and E791 used to be. I’m still trying to find the exact same gate and lab I used to go into.

Sometimes as a student you work late, and you wander around different floors. I could never get over the fact that Wilson Hall has no office numbers — at least it hasn’t had them for a long time. (There are a few office numbers these days.) One time I found a supply cabinet, and sitting there was a notebook, one of those quadrille engineering note pads. I was excited. I thought, “Could I have a notebook from Fermilab? Would I be stealing? But I’m going to use it for my summer job!” I took it, and I used it. I kind of wish I’d taken more, but I didn’t! I was a good citizen.

We Fermilab folk dress casually for work. Photo: Cindy Arnold

We Fermilab folk dress casually for work. Photo: Cindy Arnold

In the 1990s, I was a summer research student here at Fermilab, either in high school or as an undergrad. I’d worked at Burger King for a couple of summers, and then I got the job at Fermilab. I actually hadn’t been to the lab more than once when I got the job.

So I worked up the nerve to call — I’m this young kid calling Fermilab — and I said, “What’s the dress code, what should I wear? Is it a suit and tie?” And I remember the response on the phone: Whoever it was laughed and said, “There’s no dress code. It’s shorts and sandals.”

So I put on a button-down shirt with slacks and went to work at the lab. And after the first week I switched to shorts and sandals.

That was my first experience with what actual working physicists look like.

Tim Meyer is the Fermilab chief operating officer.

2000s

Bob Betz takes in the Fermilab prairie in 2003. Photo: Fred Ullrich

Bob Betz takes in the Fermilab prairie in 2003. Photo: Fred Ullrich

Dr. Robert F. Betz was a biochemist. He was also a veteran of World War II and fought in the Battle of the Bulge. Dr. Betz was known, at Fermilab, for creating and overseeing the prairie planting project.

From the early 1970s until shortly before his death in 2007, Bob worked tirelessly with Fermilab Roads and Grounds to prepare, plant, burn and monitor the Fermilab prairies. Today, we have nearly 1,000 acres here. Species by species, year by year, Bob would collect and plant the seeds and advise the Prairie Committee on how to keep building. It was always to keep building prairie. He would tell us he had prairie fever, and, if we spent too much time with him, we would catch it as well. The only known cure, he said, was to see more prairie.

Bob Betz had an influence on hundreds of prairie projects in the Midwest, most notably here at Fermilab. He also touched the lives of tens of thousands, preaching the greatness and beauty of the nearly extinct tallgrass prairie. When I was a summer student with Roads and Grounds in 2002, I traveled with Bob Lootens, Mike Becker and Martin Valenzuela to a remnant prairie in Markham, Illinois. There, in the morning, we met with Betz to collect seeds from rare plants, growing in this never plowed prairie. After a few hours in the sun, we decided to go to the local Burger King for lunch. Betz didn’t want to go to the McDonalds, which was closer. As we placed our orders and waited, Lootens pointed to Betz. I looked to see him standing by the fountain drink dispenser with a large, empty cup in his hand. We watched as he placed the cup first under Coke, then root beer, and finally a splash of Dr. Pepper.

“He must be happy about the rare species we collected with that mix of pop,” Lootens leaned in and said. Betz turned around with his characteristic, large grin. Together, we laughed.

Today the prairies at Fermilab are named for Robert Betz. A plaque marking the dedication sits inside the Main Ring.

Ryan Campbell is a Fermilab ecologist

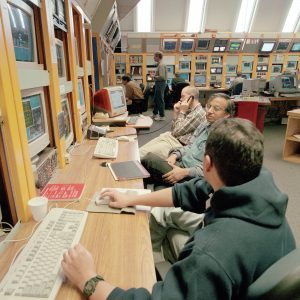

This is what the Main Control Room was like in the 2000s. But when there was an unscheduled power outage, what did these industrious folks do? Photo: Fred Ullrich

Sometime in the early 2000s, I remember, we had an unscheduled power outage. I had gotten a call at home at about 11 p.m. from someone in the Main Control Room to come in to restart my equipment since power restoration was imminent. So I made the 45-minute drive to the lab and made the right-hand turn from Pine Street toward the high-rise building (which is near the Main Control Room) just in time to see all the lights go off again. I had decided that under the circumstances, it was better for me to stick around the Main Control Room and wait for word from the power company or the people in the lab’s High Voltage Group than to make the drive back home just to turn around and come back at any moment.

Well, our group waited … and waited. We had already configured our equipment into a safe mode for when the power returned. There was nothing to do but immerse ourselves in all the line drawings sprawled out on the Crew Chief desk and debate what had happened. Nobody knew if the problem could be fixed quickly or if there was going to be an extended power outage. It would turn out to be a long wait into the morning.

Then, at about 8 a.m., I heard some commotion outside, so I decided to go see what was happening. Outside, in the Main Control Room parking lot, there was a pickup truck, and in the back of the truck was an 8-kilowatt generator. About four or five people were gathered around this generator. One person was pulling and pulling on the generator rope trying to get it started. Another one stepped in and took out the needle valve for inspection. Somebody else grabbed a hammer and started tapping on the float bowl of the carburetor. Try as they may, they just couldn’t get the engine started. Next the spark plug came out. They were all feverishly working on this generator with urgency as if it were an emergency.

I felt a sense of dedication and devotion to the lab seeing all these people pitching in to help get this generator started. I was still very new at the lab, so seeing all this teamwork made a very good impression on me. But I wondered, what was all the fuss about? What could they possibly be trying to power up after the power being off for 10 hours? The computer room? A sump pump? Was is something necessary to prevent disaster?

So I followed the huge industrial sized extension cord from the parking lot, through the doorway, and into the kitchen next to the Main Control Room, where it was plugged into a coffee pot.